From a PLM perspective, we have built up significant expertise in the area of CAD/CAM. In doing so, we support the manufacturing industry to further improve their development processes and production preparation and thus increase productivity.

We simplify the complex.

CAD/CAM

Our extensive project experience, coupled with many years of PLM perspective, will help you achieve

CAD/CAM success.

Strategy & Consulting

We assist and advise you through every CAD/CAM step:

from the idea to the machine.

First, we derive a strategy. This enables us, together with you, to design the product complexity across all components and systems. In doing so, we not only simplify complexity, but also provide constructive advice. With our strategic approach, we pursue the goal of supporting overarching design, engineering, development and manufacturing tasks and ensuring the consistent use and availability of CAD/CAM systems throughout the entire product development and manufacturing process with connection to a central PLM system.

Strategy & Consulting

We assist and advise you through every CAD/CAM step:

from the idea to the machine.

First, we derive a strategy. This enables us, together with you, to design the product complexity across all components and systems. In doing so, we not only simplify complexity, but also provide constructive advice. With our strategic approach, we pursue the goal of supporting overarching design, engineering, development and manufacturing tasks and ensuring the consistent use and availability of CAD/CAM systems throughout the entire product development and manufacturing process with connection to a central PLM system.

Postprocessors

Efficient, transparent and uncompromising.

Our postprocessors offer an unparalleled combination of efficiency, transparency and cost-effectiveness, while at the same time being lean and well thought-out. We adapt our postprocessors precisely to your requirements.

Service instead of software

In contrast to conventional software solutions, we offer our postprocessors as a service, so there are no additional costs for you after completion. We save you long-term and expensive maintenance contracts, so you retain full control over your systems. Our postprocessors ensure maximum transparency, flexibility and efficiency in your production process.

Integrated post-processor turbo

Turbo mode achieves impressive performance right from the start. The extremely short post-processor runtimes also significantly reduce waiting times for the machine operator, which minimizes downtimes and further increases the efficiency of your production. This speed is an integral part of our technology - for a faster return on investment.

NX® CAM NC Programming

We make your processes better, safer and easier.

Multifunction machine tools are of central importance for manufacturing companies. They bring enormous advantages, among other things because fewer machine types are required and setup and waiting times are reduced by complete machining on one machine. Likewise, the number of fixtures and clamping devices required is reduced. With new functions, NX® CAM helps to eliminate the high programming effort required when using these machines. And it simultaneously ensures shorter production times, which we have implemented in a large number of projects.

NX® CAM Digital Twin

The optimal combination of real and virtual world.

The digital twin as a virtual model of a physical object connects the real and the virtual world. In this context, the digital twin represents a real NC code simulation in which the real control in the NX® CAM software is mapped. Together with you, we manage to avoid machine or system failures. In the future, you will develop new products without expensive physical prototypes.

On the other hand, you receive a solution that is optimally tailored to your production. The appropriate NC code simulation, which is based on a digital 3D model of the machine and the clamping devices, can also be used with the constant aim of optimizing the manufacturing process.

CAD Design Methodology

The right method for every task area to simplify complexity.

Design needs method. Because even if you have all the tools on board, there is still no guarantee that your developers will use them in the best possible way. That's why we work together to develop design methods that are perfectly aligned with your business model.

This results in your individual, documented standards and processes. Development tools are used in the best possible way, collaboration and further processing of created designs are significantly improved. This facilitates their reuse, from which your engineering process benefits in every respect.

NX® CAD Optimization

Processes better, safer and easier.

Together, we identify your opportunities and potentials by taking stock of the current CAD/CAM and PLM landscape and the optimal integration into your business processes. We then assess and evaluate the situation in order to develop and optimize future-proof concepts for your digitalized innovation process.

CAx Integration

Connect, improve and simplify systems and processes.

Only if the various systems and processes from CAD to CAM to CAE are connected and integrated can efficient implementation succeed. Integrated systems and processes enable mechatronic product development with common data structures and continuous data flows right through to production. We integrate your applications and systems via optimized interfaces, close process gaps and standardize data flows across systems. This makes it possible to implement parallel processes in product development. The integration of development with production planning guarantees that your product can be manufactured as planned when production is released. Connected, improved and simplified.

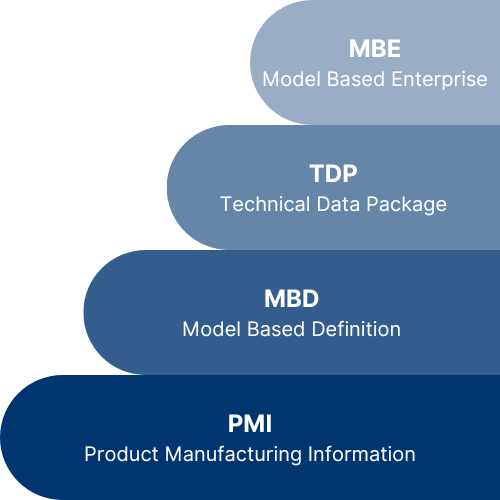

NX® MBD

From drawing to paperless development, design, manufacturing and quality control.

In the areas mentioned, drawing-based processes are still primarily in use. Through our consulting and expertise, we show you how to use your 3D models instead of your drawing in the future and how to work model-based. Following the established ECS stage model, we have developed a procedure for the introduction of Product Manufacturing Information (PMI) up to Model Based Enterprise (MBE). You decide which level you would like to climb to. We support and accompany you through consulting and individual workshops to analyze your current processes, to identify potentials, to define future processes and to pursue them in a goal-oriented way.

Training & Support

Reducing complexity can be learned - with our trainings.

We have developed special training modules for all the CAD/CAM topic areas mentioned and beyond. For these training modules we offer tailored as well as comprehensive training content. In addition, our user support also provides long-term support after the projects or trainings in order to anchor CAD-CAM sustainably, efficiently and comprehensively in the company.

Jörg Sembach

Manager CAD/CAM

We look forward to hearing from you: