Drawing-based processes are established in the areas mentioned. We will show you how to use your 3D models and work model-based so that your data flows seamlessly through your company and can be exchanged uniformly with suppliers. This will help to avoid errors in the future and make collaboration more efficient.

NX® MBD

Have you ever thought about making your development, design, manufacturing and quality control paperless?

The basics to get you started.

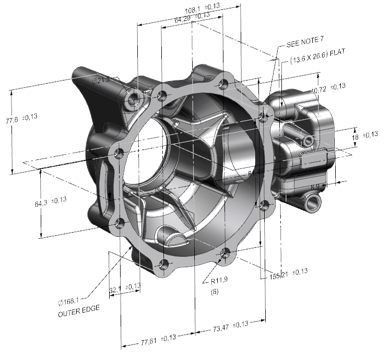

PMI - Product Manufacturing Information

MBD - Model Based Definition

MBE - Model Based Enterprise

TDP - Technical Data Package

In summary, it can be said that PMI replaces the classic drawing. With MBD, based on PMI, the 3D model becomes fully digital, more automated and can be used by both design and manufacturing. The combination of PMI, MBD and a TDP concept can lead to a fully comprehensive MBE concept early and support the way to enterprise-wide automation and paperlessness.

Challenges.

- Shorter design times

- Drawings difficult to interpret

- Disruptions have a major impact

- Errors increase costs

- Lack of 2D/3D associativity leads to quality problems

Avoid media breaks with MBD.

Today's process.

NX® CAM & Calypso | PC DMIS pull a copy of the 3D model and drawing from NX® CAD in order to then adapt it for their own needs. No common basis, but always a copy for the respective departments.

|

NX® CAD |

|---|

|

3D model |

|

PMI |

|

Drawing |

|

NX® CAM |

|---|

|

3D model |

|

– |

|

Drawing |

|

Calypso | PC DMIS |

|---|

|

3D model |

|

– |

|

Drawing |

Future Process.

All departments work with a 3D model, which provides all relevant data digitally. The 3D model replaces the drawing as the source of truth. Drawings are now only created in exceptional cases.

|

NX® CAD |

NX® CAM |

NX® CMM |

|---|---|---|

|

|

3D model |

|

|

|

PMI |

|

|

Drawing |

|

|

With NX® MBD.

- Find data based topological feature recognition

- Isolation of specific type and size

- Use of industry standard lookup tables for tolerances per bore type and size

- Create PMI size dimensions with one click

- Support for associative update

Find your way into the MBD topic with a PMI workshop from our training program.

Are you already further along in the MBD process or don't know exactly where to start? Then let our experts carry out a domain analysis to jointly formulate your individual options, milestones and goals. We will be happy to advise you.