In digital manufacturing, CAM systems are the bridge between virtual planning and real production. However, an often underestimated key component allows the seamless implementation of this planning on machine tools: the postprocessor. It translates CAM-generated data into CNC-compatible code that supplies the machine control system with the correct structures and sequences. But modern postprocessors, as an intermediary between CAM software and machine tools can do far more than just translate data - they are the key to efficiency, flexibility and competitive advantages in manufacturing.

Different machine controls have specific requirements for the structure and syntax of the data. The idea that the post-processor merely translates the tool paths of a CAM system into traverse movements is not enough these days. Modern control systems offer extensive options such as jump commands, loops and if-then conditions to optimize the machining process. With the targeted use of post-processors, machine control sequences can be improved: This leads to shorter machining times, less machine downtime and greater precision!

“The postprocessor is not everything, but without it everything is nothing”

NX software and machine tools are standardized products, but the postprocessor makes all the difference. Although OOTB (Out of the Box) solutions offer some customization options, in-house production is often more individual than expected.

Customized postprocessors can be adapted to individual requirements and allow the CAM software used to be used optimally. This enables a consistent, efficient and future-proof production concept.

Working with customers to find individual solutions

While competitors often rely on standard solutions, ECS develops postprocessors as a service in close cooperation with the customer. This paves the way to fully exploit the production potential and at the same time avoid long-term maintenance contracts. Furthermore, users benefit from maximum control over their systems and extremely short generation runtimes - ensuring a fast return on investment.

The following practical example provides an impressive example of the efficiency of customized post-processors: PTFE Nünchritz is a renowned contract manufacturer of high-quality plastic parts. As an expert in the processing of polytetrafluoroethylene (PTFE) and other high-performance plastics, the company offers a comprehensive range of services. This includes the development and manufacture of PTFE compounds, the production of PTFE semi-finished products and the machining of customer-specific sealing and construction elements

(www.ptfe-nuenchritz.de). PTFE Nünchritz positions itself as a flexible and reliable partner for individual solutions in the field of seals and construction elements made of high-performance plastics.

The initial situation

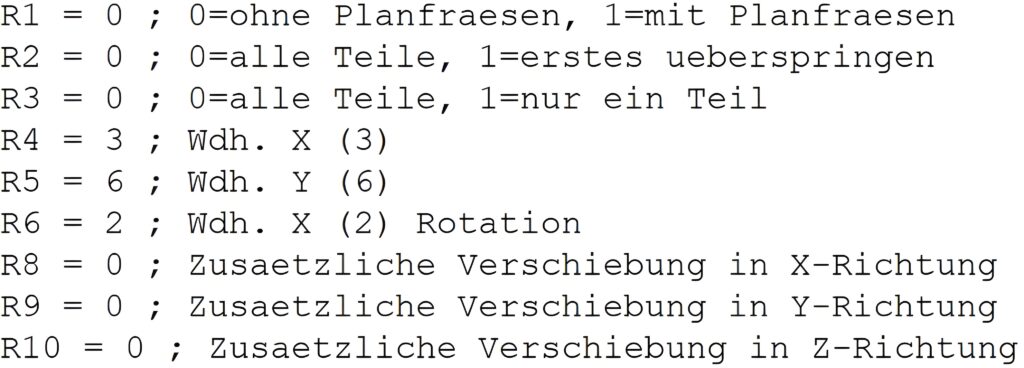

PTFE had developed a structure for the NC file: This means that the machine operator only has to enter the correct parameters at the beginning of the NC file when manufacturing repeat parts from a panel - the machining process then runs automatically. In this way, a layout of the NC file was developed that precisely meets the requirements and in which the machine operators can find their way around.

On the other hand, there is the CAM system for programming the toolpaths, with which a component is only programmed once. The NC file therefore had to be edited manually in order to insert the repeat part loops into the NC program.

The task

The existing postprocessor for single-part production was to be expanded so that it could create the complete NC program with all tool paths, the proven input structure at the start of the NC file and all loops and repetitions during the program sequence at the touch of a button.

Specifically, the following requirements had to be implemented in order to produce several identical components from one plastic sheet:

- The component should only be programmed once with all machining operations in the CAM system.

- It should be possible to completely mill over the panel (blank) once if necessary.

- It must be possible for only one component to be manufactured initially so that it can be subjected to quality control - and only after it has passed the test can the remaining components be manufactured (the first component then no longer, of course!).

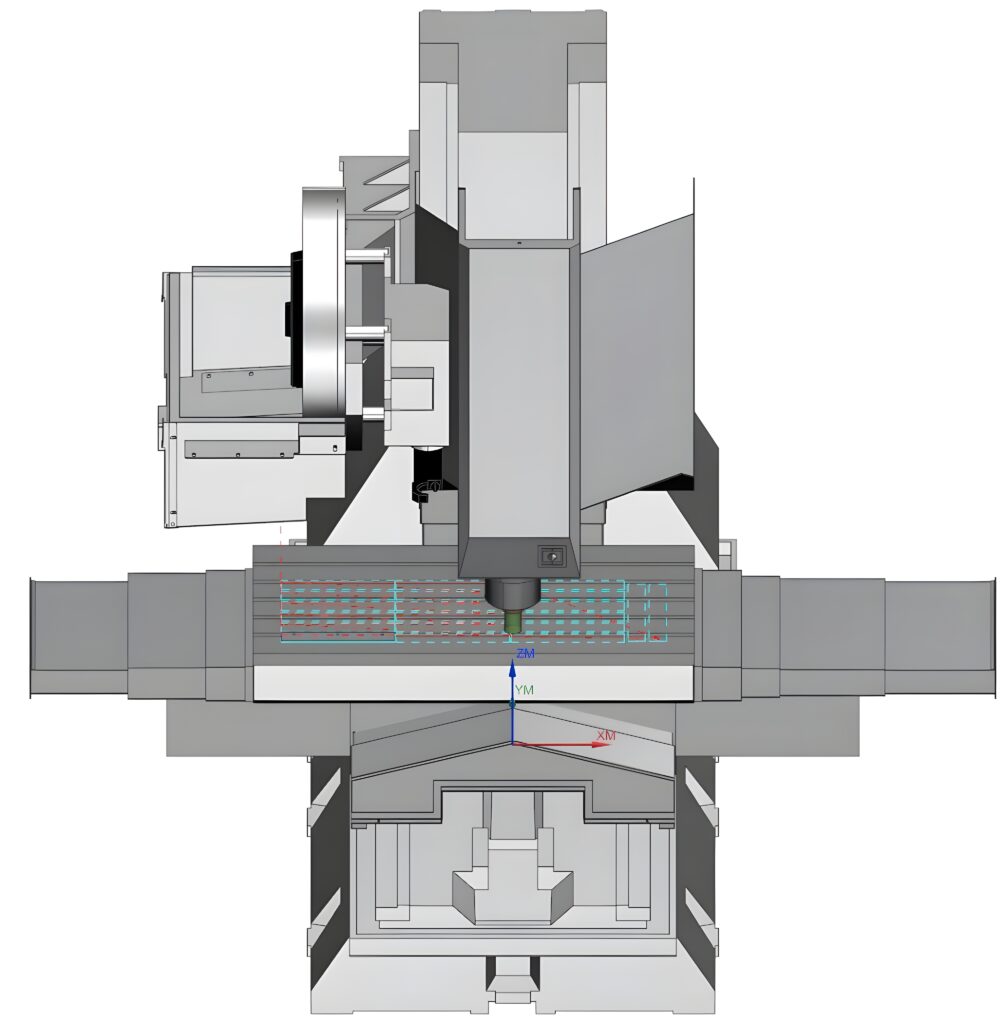

- In order to utilize the panel as completely as possible, it may be necessary to produce some components lengthwise and others crosswise (rotated) from the panel.

- It should still be possible to make minor geometric corrections to the position of the raw material.

- The structure is to be mapped to both Heidenhain and Sinumerik controls.

- During CAM programming, it must be possible to optimize the machining sequence so that the machining time is minimized with regard to tool changes and idle paths.

The ECS solution

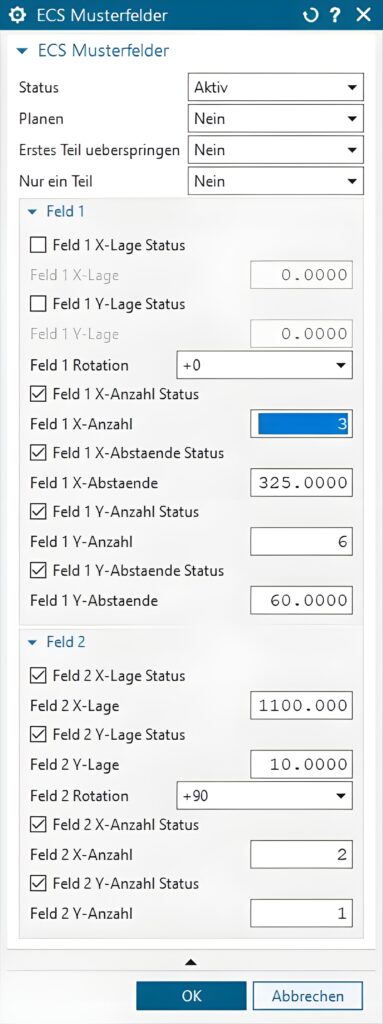

This is where ECS Engineering Consulting & Solutions from Neumarkt in der Oberpfalz comes into play. An input mask was created for the CAM programmer in which he only has to enter the key data for the repeat parts. These are the number of parts in the X and Y directions and the distances between the machining positions in the X and Y directions.

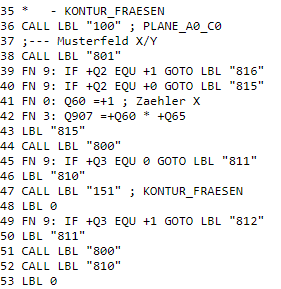

From this, the customized postprocessor solution from ECS generates a complete NC file with the following structure:

- Control parameters can be entered by the machine operator

- All toolpaths in subroutines (labels)

- Zero point calls in subroutines (label)

- the flow structure with loops and jump commands

Both Heidenhain and Sinumerik controls have been seamlessly integrated - without changing the input field for the operator. A key advantage of this solution is the automatic optimization of the

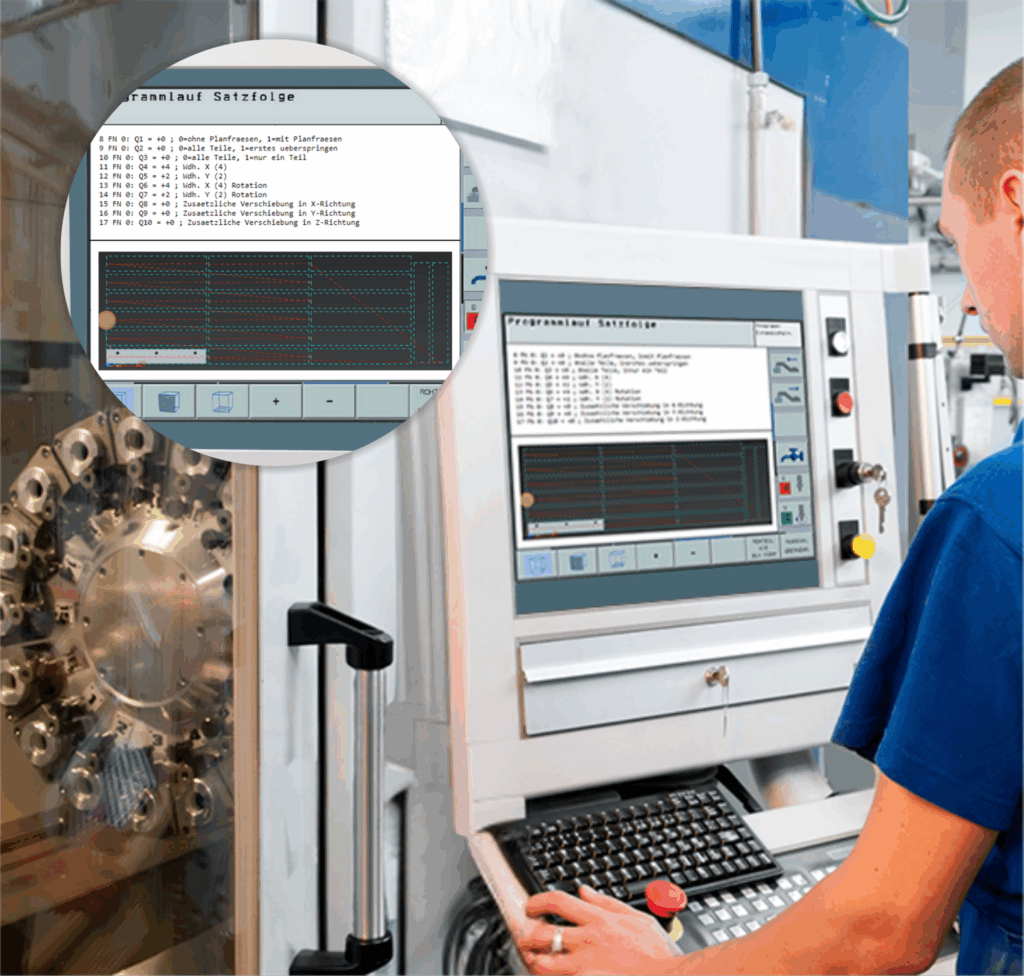

Machining sequence. Empty paths are minimized, tool changes are made more efficient and the overall machining time is reduced. At the same time, the programming effort for the CAM user remains minimal: the tool paths only need to be defined once and the key data for the pattern field entered - regardless of the control system used later. NX-CAM offers the possibility of a genuine NC code simulation: This means that the CAM programmer has an image of his real machine's geometry and control integrated in the CAM software. The NC commands can be read and processed in exactly the same way as in reality. With this ‚digital twin‘, the CAM programmer can check in advance whether the NC file has been generated correctly and whether the production sequence corresponds exactly to the planning. Thanks to this customer-specific solution, PTFE benefits from complete flexibility in production while minimizing programming effort and maximizing repeat accuracy.

Genuine competitive advantages through technological openness

The post-processors are technologically open, which means that preconfigured solutions are not used if they do not offer any added value. This allows maximum flexibility for different production requirements; necessary adjustments usually require comparatively little effort.

The customized postprocessors from ECS for individual production offer:

- Outstanding generation runtimes: Minimization of machine downtime and faster production.

- Maximum customizability: Individual NC code output exactly according to customer requirements.

- Standardized concept for the entire machine park: Simplification of NX CAM programming for all machines.

- Future-proof: ECS postprocessors remain stable even after NX updates.

- NC code machine simulation included: High fidelity thanks to direct integration in NX-CAM.

- Special interface between CAM system and machine: ECS postprocessors stand out from conventional solutions thanks to their intelligent structure.

- Open source code: ECS postprocessors are not encrypted, so they remain independent of service providers and maintenance contracts.

ECS customers also benefit from the high speed of NC file generation (post-processor run): ECS's ‚turbo mode‘ significantly reduces waiting times for the CAM programmer.

Conclusion

Post-processors are indispensable for the efficient implementation of digital production processes. Companies like PTFE show that an individually developed postprocessor not only improves production, but also saves costs in the long term and ensures competitiveness.

The tailor-made ECS solutions optimize technological processes and also provide economic benefits. With ECS expertise, customers take their production processes to the next level - efficient, flexible and future-proof.